Tupperware

From innovative kitchen products to a flexible and fun business opportunity.

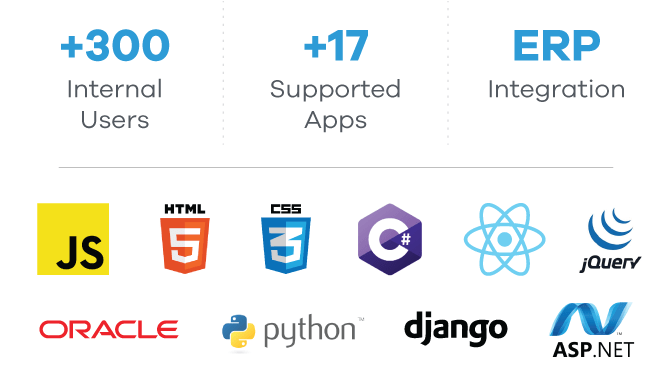

- Development and maintenance of internal applications:

- Order Management and Logistics

- Mobile frontend for store’s stock control

- Logistic transport Apps

- Integration with ERP (JD Edwards)

- Integration with Tupperware trading company